What is Dye Sublimation Printing you might ask? Have you ever wondered how those vibrant designs end up flawlessly printed on your favorite mugs, t-shirts, and phone cases? The answer lies in the magical world of dye sublimation printing. This fascinating process turns ordinary objects into customized masterpieces, and it’s surprisingly simple once you break it down.

Dye sublimation printing is more than just a method; it’s an art form that uses heat to transfer dye into different materials. Imagine it as creating a stunning tattoo for a product, with colors that won’t easily fade or peel away. It’s a clean and efficient process, perfect for both hobbyists and professional printers looking for high-quality, durable results.

Let’s dive into the colorful journey of dye sublimation printing and discover what makes it a favorite among creatives everywhere! And as always if you have any questions about the entire process of Dye sublimation in printing, Image Square Printing is just a phone call away. Their staffs are always available and eager to answer any questions that you might have.

What is Dye Sublimation Printing?

At its core, dye sublimation printing is a technique that transfers images onto materials using a special ink. But here’s the twist: the ink starts off as a solid and, with the application of heat and pressure, transforms directly into a gas.

This gas then penetrates the fibers of the material and permanently dyes it—pretty neat, right? This direct transition bypasses the liquid phase entirely, ensuring the final print is crisp and full of life.

A Closer Look at the Process

Imagine printing your design onto special sublimation paper. Next, you place this paper onto the object you want to print, whether it’s fabric or another sublimation-friendly surface. As the heat gets applied, the magic happens: the ink becomes a part of the material, leaving absolutely no residue on top.

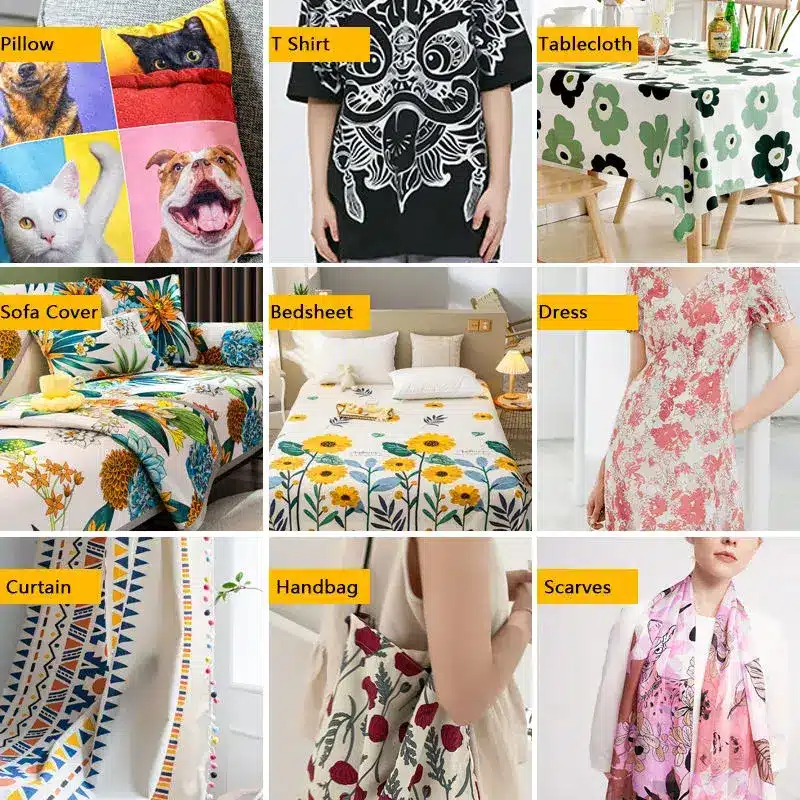

What makes it even more appealing is the durability of the prints. These designs are not only visually stunning but also resistant to cracking and fading, making them perfect for customized apparel and home goods alike.

Dye sublimation is revolutionizing how we personalize our world. With endless possibilities, it’s no wonder this printing method is a favorite among creators and manufacturers alike.

Benefits of Dye Sublimation Printing

Dye sublimation printing is a game-changer, especially when it comes to producing vibrant, full-color designs. One major perk is its ability to create prints that virtually pop off the fabric, offering colors that are brighter and richer than some other printing methods can achieve.

Another fantastic benefit is durability. Because the inks become part of the material, sublimation prints are incredibly resistant to fading. They can withstand repeated washes without losing their vibrancy. This makes them perfect for everyday items like clothing and mugs, ensuring they still look fresh after countless uses.

But that’s not all. The quality of detail achieved with dye sublimation is top-notch. Whether you’re working with intricate patterns or sharp lines, you can expect high-precision finishes that truly capture the essence of your design. This makes it a favorite for producing high-resolution images and designs that need to maintain their sharpness.

So, if you’re looking for a printing method that checks all the boxes for vividness, durability, and detail, dye sublimation is definitely worth considering. It’s like magic for your custom designs!

Materials Needed for Dye Sublimation Printing

Before you can dive into the world of dye sublimation printing, you’ll need to gather some essential materials. Let’s start with the basics, which include a dye-sublimation printer. This machine is specifically designed to handle special sublimation inks, making it a key player in the printing process.

Sublimation Paper and Ink

Next up is sublimation paper. It’s different from regular paper because it’s specially coated to hold and release sublimation inks effectively. On the topic of inks, you’ll want to use sublimation inks that turn into gas when heated, allowing them to transfer seamlessly onto your chosen surface.

A heat press machine is also crucial. It’s what you’ll use to apply the right amount of heat and pressure to transfer the ink from the paper to your product, whether it’s fabric, ceramic, or metal. Each material might require some adjustment to the heat and time settings, but that’s part of the fun experimentation!

Last, but certainly not least, you’ll need substrates that are prepared for sublimation. These could be polyester fabrics or specially coated items like mugs or phone cases. It’s important because the sublimation process only works on these types of surfaces.

Once you have all these materials, you’re well on your way to creating exciting and lasting sublimation prints!

Step-by-Step Dye Sublimation Process

Let’s walk through the dye sublimation process step-by-step. You’ll find it’s straightforward once you’ve got a handle on all the materials.

First, start by creating your desired design using design software. Make sure it’s vibrant, as sublimation works best with bright and bold colors. Once your design is ready, print it onto the sublimation paper using your dye-sublimation printer.

Now that you have your printed design, it’s time to prepare your substrate. If it’s a fabric, give it a quick lint roll to ensure a clean surface. For hard items, a dust-free surface is key.

Next, align the printed sublimation paper with your substrate. Use heat-resistant tape to secure it, which prevents any shifting during the transfer process.

Move over to your heat press machine. Adjust it to the correct temperature, pressure, and time settings as recommended for your material. Once set, place your item in the heat press, cover it with a protective sheet, and close the heat press.

After the timer beeps, carefully open the heat press and peel away the sublimation paper. Your design should be beautifully transferred and vibrant. Let it cool briefly, and voila! You’ve completed the dye sublimation process.

That’s all there is to it! With practice, you’ll master the art of dye sublimation in no time.

Ensuring Quality Results in Dye Sublimation Printing

Achieving top-notch quality with dye sublimation printing often hinges on a few key practices. First up, focus on choosing the right materials. Opt for high-quality substrates specifically designed for sublimation to ensure vibrant color transfer.

Pay close attention to your printer settings. Make sure your printer is well-maintained, with a clean print head and suitable ink levels. Adjust the settings to match the resolution and paper type being used, as this affects how well the image prints on the paper.

Don’t skip on testing. Running a test print helps you spot and tweak any issues before committing to the final product. It’s a great way to save time and resources.

Mind the heat press parameters. Double-check that the temperature, time, and pressure settings are spot-on for your specific substrate. These elements play a crucial role in how well the ink bonds with the material.

Lastly, remember the importance of cooling. Allow your sublimated items to cool naturally to prevent any accidental smudging or distortion.

By keeping these pointers in mind, you’ll produce beautiful, professional results every time, making all your projects shine!

Choosing the Right Printer for Dye Sublimation

Picking the perfect printer for dye sublimation can feel a bit overwhelming, but it becomes easier when you know what to look for. First, consider the printer size. Think about the types of projects you’ll be handling—is large-format printing something you’ll need regularly?

Understanding Ink Compatibility

Ensure the printer is compatible with dye sublimation inks. Not all printers are designed to handle these inks, so it’s important to verify their suitability to prevent any mishaps or ineffective results.

Another key factor is resolution. High-resolution capabilities are crucial for sharp, detailed images. Always check the specs to ensure the printer delivers the clarity your work requires.

Budget also plays a role. Prices can range widely, so identify what features are essential for your needs and compare them against your budget. Remember, sometimes investing a bit more upfront can save hassles down the line.

Finally, read reviews and maybe even try to see the printer in action if possible. Getting firsthand feedback from other users can provide valuable insights into performance and potential issues.

With these points in mind, you’re all set to choose a printer that meets your dye sublimation needs, ensuring quality results every time!

The Bottom Line: Mastering the Dye Sublimation Printing Process

Wrapping up, mastering the dye sublimation printing process is much like learning any new craft. It might seem daunting at first, but once you grasp the essentials, it becomes second nature.

First off, understanding your materials and tools, like choosing the right printer, is crucial. It sets the foundation for everything that follows. Don’t skip out on learning the nuances of printer settings and ink compatibility—it can save a ton of time and money.

In light of this, practice is key. Experiment with different designs, textiles, and surfaces. Each trial, whether a success or a stumble, teaches something new. Over time, your skills will become sharper, and the process smoother.

It’s also worth mentioning that staying curious helps. Follow trends, watch tutorials, and engage with fellow enthusiasts. There’s always something new to learn or try, and continuous learning keeps the process exciting and fresh.

While challenges will arise, remember, each hurdle is a stepping stone to becoming better. Embrace any mistakes as part of your journey and don’t hesitate to seek help when needed.

At the end of the day, dye sublimation opens up a world of possibilities for expressing creativity and producing stunning prints. With persistence and the right mindset, you’ll soon find yourself not just understanding but truly mastering the dye sublimation printing process.